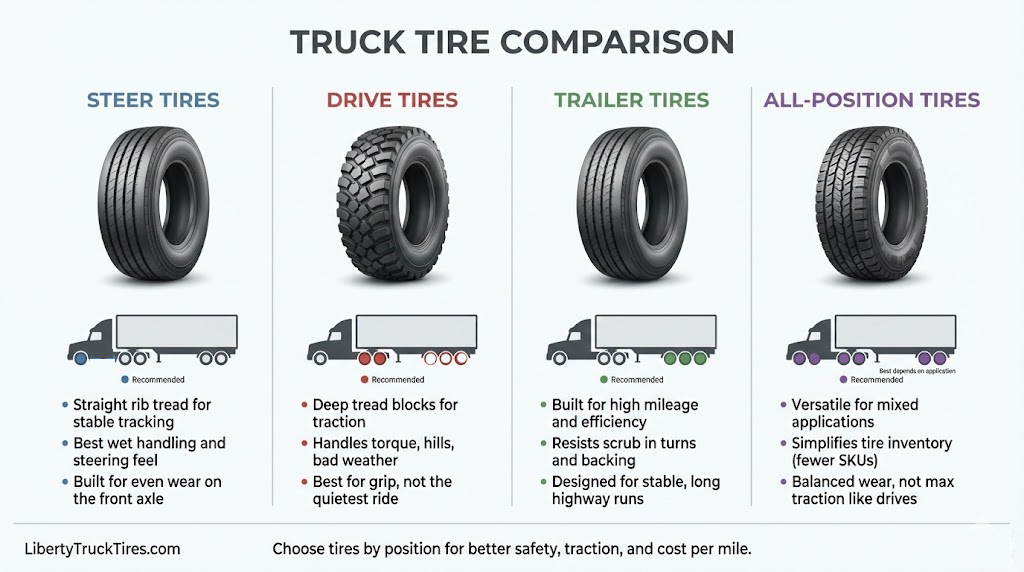

Buying the right commercial truck tires is not just about finding the right size. The tire’s position on the truck matters just as much as the brand, tread depth, or price. A tire that performs great on a trailer can wear fast on a steer axle. A tire made for drive axles can be noisy and uncomfortable up front. An all-position tire can be a smart “one tire for many jobs” option, but it is not always the best choice for every axle.

In this guide, we will break down the key differences among steer tires, drive tires, trailer tires, and all-position tires, what each is designed to do, and how to choose the best option for your operation.

A semi-truck and trailer setup applies tires to very different types of stress, depending on where they are mounted.

Steer axle tires carry heavy front-axle load, manage steering response, and handle water evacuation for safety.

Drive axle tires must transmit engine torque to the road and provide traction on wet, snowy, or loose surfaces.

Trailer tires take a beating from scrubbing in tight turns and long highway miles, while carrying consistent loads.

All-position tires aim to balance performance across multiple axle roles, often at the expense of trade-offs.

If you match the tire type to its job, you typically get better mileage, safer handling, and more predictable wear.

Steering tires are mounted on the truck’s front axle. They handle the most important job in your whole setup: keeping the rig stable and controllable at speed.

Steer tires usually feature rib-style tread patterns (straight grooves) for tracking stability, strong wet traction and water evacuation to reduce hydroplaning, and designs that help promote even wear and better ride comfort. They also support precise steering response, which matters every time you correct the wheel at highway speed.

Steer tires often show problems first if something is off: misalignment, incorrect inflation, or worn suspension components. Because steer tires affect safety and handling directly, most fleets prioritize quality and correct spec here.

Browse: Steer Tires

Drive tires mount on the powered axles. Their job is to convert engine power into forward movement with maximum grip and controlled wear.

Drive tires typically feature deeper, more aggressive tread patterns for improved traction. They include more biting edges and block designs to handle wet roads, snow, or slush, loose surfaces, and steep grades. They also use durable compounds that help resist chunking and irregular wear under torque.

You notice the difference in poor weather, hills, stop-and-go routes, and regional work that includes mixed road conditions. Drive tires can create more road noise than steer tires because of the tread block design, but that noise is often the price of real traction.

Browse: Drive Tires

Trailer tires mount on the trailer axles. Trailers do not deliver power, but they create their own kind of tire abuse, especially during turning and backing.

Trailer tires often prioritize high mileage and fuel efficiency on highway routes, scrub resistance in tight turns, and stable tracking. Many trailer-focused designs aim to reduce rolling resistance, which can help fuel economy over long runs.

Some tires are labeled trailer because they perform best under those conditions. In most fleets, trailer tires get selected to optimize cost per mile, stable wear patterns, and lower rolling resistance for long-distance hauling.

Browse: Trailer Tires

All-position tires are built to perform across multiple wheel positions. Many fleets use them for mixed applications, simplified inventory, and certain regional routes.

All-position tires usually provide balanced tread designs that can handle steering duties and steady highway miles. They tend to deliver predictable wear and stable handling, making them a practical “do-it-all” option when you need flexibility.

All-position does not automatically mean best everywhere. It means good in many roles, but not always the top performer in one specific job. A dedicated drive tire often beats an all-position tire in traction. A dedicated steer tire may offer better steering feel and wet handling. A dedicated trailer tire may deliver better low rolling resistance for long highway runs.

Browse: All-Position Tires

Steer tires: safety, steering control, wet handling, smooth wear

Drive tires: traction, torque handling, grip in bad weather

Trailer tires: long mileage, scrub resistance, stability, efficiency

All-position tires: versatility, simplified inventory, balanced performance

If you run mostly on highways, trailer tires and some all-position models often win for efficiency and wear. If you do regional and mixed routes, all-position can be helpful, but drive traction still matters. When operating on snow, on hills, or in harsh weather, tire traction is the priority for the powered axles.

If traction is the priority, you usually want a true drive tire on the powered axles. When mileage and fuel economy are the primary criteria, trailer tires and rib-style designs often win. If you want flexibility and fewer SKUs to stock, all-position can be a smart compromise.

If you see cupping, feathering, shoulder wear, or fast wear on one side, tire type alone will not fix it. Check alignment, inflation habits, suspension wear, and axle condition. Tire selection is most effective when the truck is mechanically sound.

Putting aggressive drive tires on a trailer and expecting perfect wear

Choosing the cheapest option for steer position and losing stability and even wear

Assuming all-position equals best on every axle

Ignoring inflation and alignment, then blaming the tire

Each tire position has a specific role, and the best-performing tire is the one built for that role. When you match tread design and tire construction to the axle, you usually get better control, longer tire life, and a lower cost per mile.